Reverse Engineering Services

Reverse Engineering Services

We quicken your product development process and modernize your processes at affordable price to innovate constantly in today's competitive market, you must generate new ideas and implement them quickly in your product. Is it difficult to assess different parts of any equipment using traditional geometric measurement techniques? Then, the best option for you would be to outsource reverse engineering services to an experienced service provider.

StepsIN is a leading reverse engineering services company which can help you get detailed 3D models from physical parts of any product or equipment so that you can utilize them to improvise design while keeping manufacturability and the development process in mind. We leverage the latest technologies to deliver top quality services to our clients.

Our team can do the complex reverse engineering and adhere the below points to do the best customer services and satisfaction

- On-time delivery

- High accuracy

- Nominal price

We have experience working with the latest reverse engineering tools and technologies. We have the required skills to create relevant drawings and models required for the project in any desired format.

Our team at FWS has the required skills and expertise to provide you with part scanning services including CMM, 3D laser, CGI, etc.

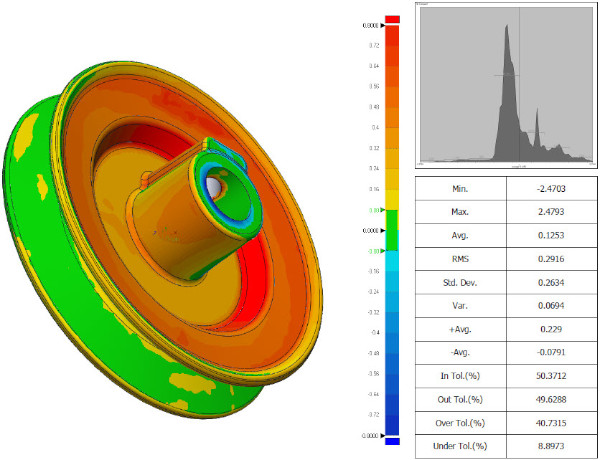

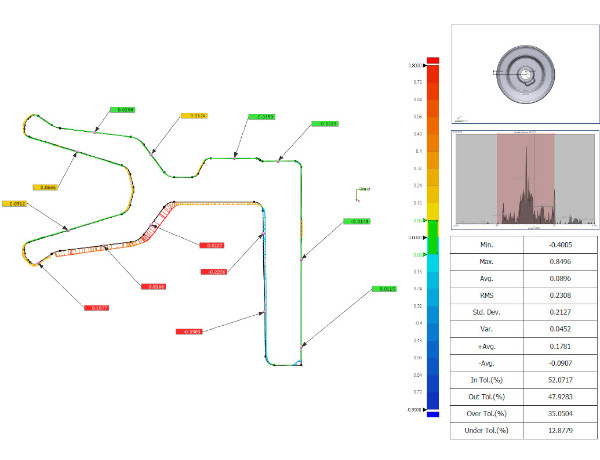

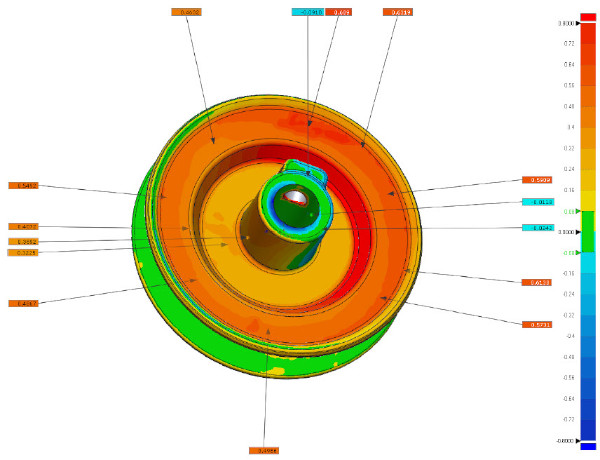

We provide clients with Computer-Aided Inspection (CAI) and Computer-Aided Verification services which ensures that it improves the production process of your company. It ensures constant and precise material and dimension consistency.

We monitor the changes to a part over its lifecycle. This ensures that the part undergoes better maintenance, improved future designs, and better forecasting of failure and reliability.

Our team will provide the client with the exact specifications of the part which will enable the client to know exactly what they have and they will be needing in the future.

Reverse Engineering Techniques We Control

Apart from traditional manual geometric designs, we utilize the following techniques to offer cost-effective reverse engineering services to our clients

- Non-contact Inspection

- Coordinate Measuring Machine (CMM) Scanning

- Portable CMM Scanning

- Full Contact CMM Scanning

- 3D Laser Scanning

Reverse Engineering Process We Follow

Being a leading reverse engineering service providing company, we believe in providing quality services within quick turnaround time. This is possible by making use of a streamlined and systematic process. The key steps involved in our process are -

Receive Parts

In the first step, we receive the parts and the physical components from the client for our team's review at StepsIN Solutions.

Scanning

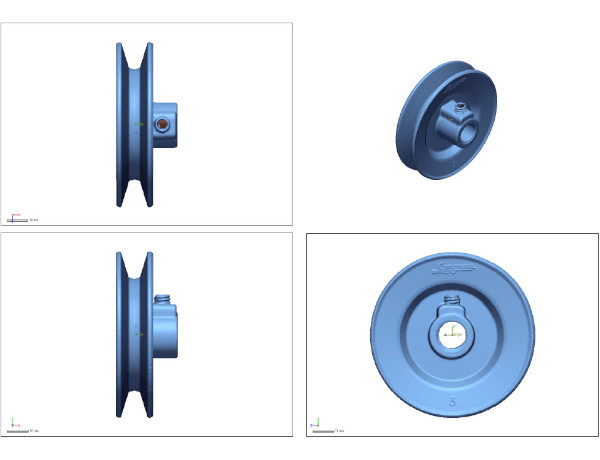

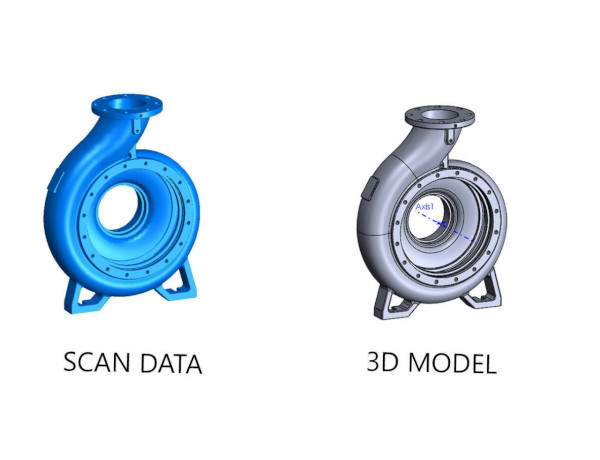

Our team at FWS performs a laser scan of the part and extract the crucial cloud point data to our systems.

Modeling

Using the cloud point data, our team generates a 2D/3D model which can be used to enhance the product. This includes inspection, failure analysis, general study, reproduction, etc.

Why Choose StepsIN for Reverse Engineering Services?

The major advantage of our services is that you get skilled engineers to work on your projects quickly and cost-effectively. Some of the key reasons to choose us include -

- Flexible pricing options to suit your business requirements and budget

- Easily scalable services and can ramp up service requirement as and when required

- Get comprehensive insight into competitor's products

- Analyze your products and their parts in detail to develop the most efficient development plan

- Reduce product development cost by building prototypes in digital format

- Minimize time-to-market with faster testing of prototypes and optimized development process

Machine Details

Kreon Laser Line Probe specifications

- Accuracy: 48μm

- Repeatability: 15μm, 2σ

- Scan Width: 200mm

- Scan Rate: 6,00,000 pts/sec

- Max. frequency: 300 Hz

Kreon Contact Probe Specifications

- Measuring Range: 2.5m (8 ft), 7 axes

- Single point Repeatability: 27μm

- Volumetric Accuracy: 0.038mm